Hyundai Motor Group Hosts Pleos SDV Standard Forum to Drive Software-Defined Vehicle Era through Collaboration

- Hyundai Motor Group aims to lead the SDV era with its partners, addressing rapid industry shifts and accelerating the transition to a software-focused paradigm

- The forum introduces a new collaboration model to drive innovation across the value chain and establish a software-centric ecosystem for SDV development

- The Group presents a technology roadmap to drive SDV innovation and establish an aligned supply chain based on the values of speed, transparency and trust

- The event features keynote speeches and technical sessions addressing topics, such as: E&E architecture, vehicle OS and security, diagnostics and standardization

Hyundai Motor Group (the Group) has reinforced its leadership in the software-defined vehicle (SDV) era by sharing the latest technology standards and software development system with its key partners, strengthening the foundation for collaboration.

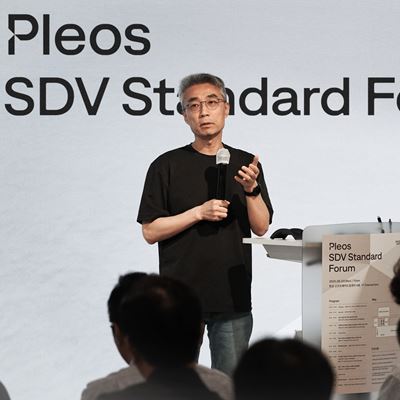

Today, the Group hosted the ‘Pleos SDV Standard Forum’ at the Software Dream Center in Pangyo, Korea. The event brought together core engineering leaders from 58 key partners, including Hyundai Mobis, Hyundai Kefico, Bosch, Continental, HL Mando, and other vehicle control system specialists.

This forum, held as the automotive industry undergoes a major shift from hardware to software-centric development, aimed to accelerate the transition to SDVs. It serves as a way to transform supply chains and enhance the industry’s adaptability to this transformation.

“Close collaboration with key partners and the widespread adoption of standardized development frameworks are essential for implementing SDVs,” said Chang Song, President and Head of the Advanced Vehicle Platform (AVP) Division at Hyundai Motor Group. “We will continue to establish a software-driven collaborative network by distributing technical standards and building a supply chain system for SDV mass production.”

Unlike traditional hardware-based vehicles, SDVs are defined as platforms capable of ongoing updates and feature expansions even after delivery. Achieving mass production of SDVs requires a complete reorganization of development environments across all areas, including component suppliers, software developers and specialists in diagnostics, security and verification. To support this shift, standardized frameworks and collaborative ecosystems are essential.

Through the forum, the Group shared the latest technical standards and development frameworks required for the SDV transition, enabling the establishment of a software-centric collaboration system to accelerate industry advancements.

The forum began with a keynote speech from President Song and featured five key sessions, including:

- Transitioning vehicle development methods for SDV mass production.

- Applying CODA[1] (Computing & I/O Domain-based E&E Architecture) for developing optimized hardware and flexible software architecture.

- Facilitating vehicle software development based on the Pleos Vehicle OS.

- Establishing a standardized, scalable framework for external devices (Plug & Play).

- Developing integrated software tools to foster collaboration between OEMs and suppliers.

These sessions expanded on the strategies presented at the ‘Pleos 25’ developer conference in March. Executives and technical leaders from Hyundai Motor, Kia and 42dot — the Group’s global software center — presented strategies to address the challenges of the SDV transition and engaged in panel discussions and Q&A interactions.

One key highlight was the introduction of a standardized software development framework to support SDV development. This framework provides detailed guidelines for partners to adopt it within their own development environments and covers the entire development process — from defining specifications to feature validation, issue management and tracking outputs. A standout feature is the ability for the Group and its partners to securely connect and share development data in real time, ensuring seamless collaboration while maintaining data security.

The adoption of this standardized framework is expected to significantly enhance the efficiency and quality of software development by integrating the expertise of various partners working on vehicle control units. Moreover, this transition marks a shift from the traditional hardware-focused vertical supply chain to a software-driven, horizontally integrated collaboration model. It is anticipated to form the critical infrastructure for large-scale SDV production.

Through this forum, the Group aims to support its partners in discovering new business opportunities aligned with the SDV era. It plans to continue operating regular forums, sharing technical roadmaps, and accelerating the transformation of development environments through ongoing collaboration.

At the ‘Pleos 25’ developer conference in March, the Group launched its integrated software platform brand ‘Pleos’, unveiling plans for an in-vehicle app ecosystem and global partnerships to advance its transformation into a software-first mobility tech company.

[1] CODA: A design approach for vehicle networks and controllers, organized by data processing and input/output management using high-performance vehicle computers and domain-specific controllers.